Modular Trailer

Conquer the impossible with our Modular Trailers. Featuring advanced hydraulic systems and adaptable configurations, we provide the ultimate solution for industrial module transport and mega-project logistics worldwide.

What is Modular Trailer?

A modular trailer, often referred to as a Hydraulic Modular Trailer (HMT), Multi-Axle Trailer, Heavy Lift Transporter, or more broadly, a Platform Trailer, is a highly sophisticated and versatile transport system designed for moving exceptionally heavy, oversized, and non-divisible loads that conventional trailers simply cannot handle. Unlike standard trailers, a modular trailer consists of individual, interconnected modules, each equipped with multiple axle lines and an advanced hydraulic suspension system. These modules can be combined in various configurations – side-by-side, end-to-end, or in complex arrays – to create a custom transport platform precisely tailored to the dimensions and weight of the cargo.

Modular Trailer for sale

No products were found matching your selection.

hydraulic modular trailer application scenarios

Modular trailers are the workhorses of mega-projects, providing the essential logistical backbone for moving components that are too heavy, too large, or too complex for any other mode of transport. Their adaptability allows them to operate in diverse and challenging environments globally.

Oil & Gas Industry: Transporting colossal refinery components like pressure vessels, reactors, heat exchangers, crude oil distillation columns, and entire pre-assembled modules to remote project sites.

Power Generation: Moving massive generators, turbines, transformers, stators, and nuclear reactor components for thermal, hydro, and nuclear power plants.

Infrastructure Development: Hauling pre-fabricated bridge sections, tunnel boring machines (TBMs), large precast concrete segments, and specialized construction equipment.

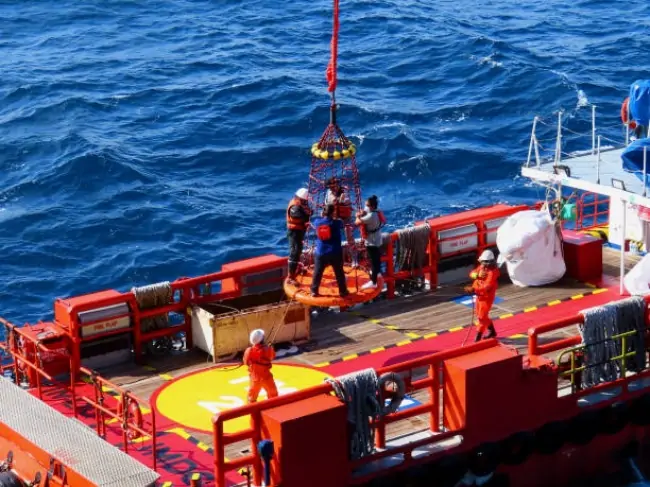

Shipbuilding & Offshore: Relocating large ship blocks, offshore drilling rig components, and entire vessel sections within shipyards or to launch sites.

Mining & Metallurgy: Transporting oversized mining machinery, crushers, grinding mills, and large ore processing equipment.

Heavy Manufacturing: Moving large presses, industrial machinery, and other non-divisible heavy components within factories or for inter-plant transfers.

Standard configuration

-

SUNSKY axle

-

12R22.5 Tires

-

LED light system

-

Q550D steel

-

surface paint process

-

Leaf spring suspension

-

Engine

Customizable options

-

Payload

-

Platform size

-

Deck type

-

Steering system and controls

-

Hydraulics

-

landing gear

-

Safety and lighting

Looking for some new designs ?

hydraulic modular trailer detail design

The pipes in the frame are bent by fully automatic CNC to reduce errors caused by human factors. All joints use high-precision torque wrenches to ensure the safety of the joints.

The operation box is optimized, and all the instruments are placed on the top for easy observation. The interior is all made of seamless steel pipes, which are sturdy and durable.

The gooseneck is equipped with a high-pressure accumulator to protect the steering pipeline when overloaded. The accumulator can be filled with nitrogen, and it is the only manufacturer in China with nitrogen equipment.

The hydraulic hard pipe uses the global seamless steel pipe, and the hydraulic hose uses the eaton four-layer steel wire hose, which is the same as Goldhofer.

The side adopts the appearance of Goldhofer and is equipped with a hanger for easy bundling and hoisting.

The joint surface is processed by gantry milling as a whole, which is more accurate and the joint surface is seamlessly connected.

Video of modular trailer

Hydraulic Modular Platform Trailer

heavy-duty modular trailer

The trailer type you are looking for is not found

FAQ

What types of loads can a modular trailer handle, and what makes it so versatile for extreme heavy haul?

A modular trailer, also known as a Hydraulic Modular Trailer (HMT) or Self-Propelled Modular Transporter (SPMT), is specifically engineered to handle an extraordinary range of super heavy, oversized, and non-divisible loads that are simply impossible to move with conventional transport equipment. Its versatility stems from its unique design, which allows individual platform modules to be interconnected in various configurations, creating a customized transport solution for virtually any size or weight. This means a modular trailer can transport individual components weighing hundreds or even thousands of tons, with dimensions stretching tens of meters in length, width, and height.

Typical loads include massive industrial modules for refineries and petrochemical plants, such as distillation columns, pressure vessels, and heat exchangers, often pre-fabricated off-site to save time and cost. In the power generation sector, heavy lift transporters are crucial for moving colossal transformers, generators, and entire turbine assemblies for thermal, hydro, and nuclear power plants. For infrastructure projects, multi-axle trailers are indispensable for hauling pre-fabricated bridge sections, large concrete girders, tunnel boring machines (TBMs), and other immense construction elements. The shipbuilding industry utilizes them to move colossal ship blocks and even entire vessel sections within shipyards or to launch sites. Mining operations rely on these heavy haul platforms for transporting oversized mining excavators, crushers, and processing equipment. Furthermore, specialized applications include moving historical buildings, large art installations, or even damaged structures for demolition or repair. The modularity allows for the exact number of axle lines and the precise platform dimensions required, while the hydraulic suspension system ensures even load distribution and precise height adjustment, enabling transport over varied terrain and under challenging overhead clearances. This unparalleled adaptability makes the modular trailer the go-to solution for the most demanding heavy transport logistics globally.

How does the modularity of these trailers work, and what are the benefits of configuring different setups?

The modularity of modular trailers is their defining characteristic and the key to their unmatched versatility in super heavy haul operations. Essentially, a modular trailer system is composed of standardized, independent units, each featuring a robust frame, multiple hydraulic axle lines, and a dedicated control interface. These individual modules, whether they are 2-axle, 3-axle, 4-axle, or 6-axle units, are designed with universal mechanical coupling points and hydraulic/electrical connections. This ingenious design allows them to be connected in virtually limitless combinations.

Benefits of configuring different setups are profound: Firstly, it offers unprecedented scalability. Need to move a 500-ton transformer? Combine several 4-axle modules side-by-side or end-to-end to create a platform with the required load capacity and footprint. For a 2,000-ton refinery column, dozens of modules might be interconnected into a vast, synchronized transport system. This “building block” approach means a single fleet of modular units can handle a wide range of cargo weights and dimensions, eliminating the need for a separate specialized trailer for every unique load.

Secondly, it provides optimal load distribution. By adding more modules, the total weight of the cargo is distributed over a larger number of axle lines, significantly reducing ground pressure. This is crucial for navigating roads, bridges, and soft ground that might otherwise be unable to support the concentrated weight of a single heavy load. It also helps in complying with strict regional axle load regulations.

Thirdly, enhanced maneuverability and stability. While seemingly counter-intuitive for such large configurations, the ability to control each axle line independently and collectively (as detailed in FAQ #4) means even a vast heavy lift transporter array can execute complex turns or move sideways with precision. The hydraulic suspension system further ensures that the load remains stable and level, even on uneven terrain, adapting to changing ground conditions in real-time.

Finally, cost-effectiveness and resource optimization. Instead of owning numerous highly specialized, single-purpose trailers, a company can invest in a modular fleet that can be reconfigured for countless projects. This maximizes asset utilization, reduces capital expenditure on diverse equipment, and streamlines logistics by offering a single, adaptable solution for oversized cargo transporter needs. The modularity of these heavy haul platforms is what truly elevates them beyond conventional heavy transport solutions, making them the ultimate tool for complex project logistics.

What advanced steering and suspension systems do modular trailers employ to manage extreme weights and tight spaces?

Modular trailers, whether they are Hydraulic Modular Trailers (HMTs) or Self-Propelled Modular Transporters (SPMTs), are equipped with some of the most advanced steering and suspension systems in the heavy transport industry, crucial for managing extreme weights and navigating tight spaces. The core of their sophistication lies in the hydraulic axle lines. Each wheel bogie (an assembly typically containing 2 or 4 tires) is mounted on a hydraulic cylinder that allows it to move independently in the vertical plane. This hydraulic suspension serves multiple critical functions:

Firstly, it provides active load leveling and compensation for uneven terrain. When traversing unlevel ground, the hydraulic system automatically adjusts the height of individual axle lines, ensuring that the colossal load is always evenly distributed across all axles and that the trailer remains stable. This prevents undue stress on the cargo and the trailer structure itself, protecting valuable assets. This adaptive suspension also allows for precise height adjustments, enabling the heavy lift transporter to lift loads off supports or lower them onto foundations with pinpoint accuracy, eliminating the need for separate jacking equipment in many scenarios.

Secondly, the multi-directional steering system is unparalleled. Unlike conventional trailers with only front-axle steering, every axle line on a modular trailer can be steered independently. This is achieved through a sophisticated electronic control unit (ECU) that synchronizes the movement of all wheels. Operators, often using a wireless remote control, can select from various steering modes:

- All-wheel steering: All wheels turn in the same direction, allowing the entire multi-axle trailer to execute tight turns.

- Diagonal (Crab) steering: All wheels turn at the same angle in parallel, enabling the trailer to move sideways like a crab, crucial for maneuvering in extremely confined spaces or aligning loads precisely.

- Pivot steering: The trailer can rotate around a specific central point, effectively allowing it to turn within its own footprint, essential for very tight turns or changing direction without significant forward/backward movement.

- Transverse steering: Allows the trailer to move perpendicular to its longitudinal axis.

This combination of independent hydraulic suspension and highly advanced, synchronized multi-directional steering ensures that modular trailers can safely and precisely maneuver colossal loads through complex industrial plants, congested urban areas, and challenging construction sites, overcoming obstacles that would be impossible for any other transport method.

How does regular maintenance contribute to the longevity and reliability of a complex modular transport system?

Regular and meticulous maintenance is absolutely paramount for ensuring the longevity, reliability, and safe operation of a complex modular transport system, such as a Hydraulic Modular Trailer (HMT) or a Self-Propelled Modular Transporter (SPMT). Given the immense loads they carry and the precision required for their operation, even minor defects can lead to catastrophic failures, costly project delays, and significant safety risks.

Key areas of maintenance include:

- Hydraulic System Integrity: This is the lifeline of the trailer. Regular checks of hydraulic fluid levels, quality, and contamination are critical. Hoses, fittings, cylinders, and pumps must be meticulously inspected for leaks, wear, or damage. Proactive replacement of seals and components, along with scheduled fluid changes, ensures optimal pressure, precise control of axle lines, and reliable steering. Any degradation in the hydraulic system can compromise load leveling, steering accuracy, and overall stability.

- Structural Inspection: The high-strength steel frame, chassis, and coupling points are subjected to immense stress. Regular visual and non-destructive testing (NDT) inspections for cracks, deformations, or fatigue in welds are crucial. Any signs of structural integrity compromise must be addressed immediately to prevent catastrophic failure under load. This includes inspecting the deck, bolster attachments, and all load-bearing components.

- Axle Lines & Suspension Components: Each individual axle line, including tires, bearings, brakes, and suspension linkages, must be thoroughly inspected for wear, damage, and proper alignment. Tires are particularly critical given the heavy loads, requiring regular pressure checks and rotation. The complex steering mechanisms also need lubrication and adjustment to ensure smooth and synchronized movement.

- Electrical & Control Systems: For SPMTs, the Power Pack Unit (PPU) requires routine engine maintenance (oil changes, filter replacements). The sophisticated electronic control units (ECUs), wiring harnesses, sensors, and remote controls need regular diagnostics and calibration. Faulty electrical connections or sensor errors can severely impact steering precision, safety interlocks, and operational efficiency.

- Coupling Mechanisms: The robust pins and interlocking systems used to connect modules (both longitudinally and side-by-side) must be inspected for wear, damage, and proper engagement. Lubrication is essential to ensure easy and secure assembly/disassembly, which is fundamental to the trailer’s modularity.

- Cleaning & Corrosion Prevention: Given that these trailers often operate in harsh environments (construction sites, industrial plants, coastal areas), regular cleaning to remove dirt, debris, and corrosive agents is important. Application of anti-corrosion coatings and touch-up paint where necessary helps preserve the structural integrity and extends the lifespan of the steel components.

A rigorous preventive maintenance schedule, performed by highly trained technicians, not only ensures the modular transport system’s operational reliability and safety but also significantly extends its service life, preserving a substantial investment and ensuring consistent performance for even the most demanding oversized cargo transporter projects.

What are the crucial safety considerations and regulatory requirements for operating a modular trailer with super heavy loads?

Operating a modular trailer with super heavy loads demands an unparalleled level of safety consideration and strict adherence to numerous regulatory requirements, making it one of the most meticulously planned operations in heavy transport. The sheer scale and complexity of the loads necessitate a comprehensive approach to safety, extending far beyond typical road transport.

Key Safety Considerations:

- Comprehensive Planning & Risk Assessment: Every single super heavy haul operation begins with extensive engineering studies, route surveys (identifying bridge capacities, overhead clearances, road widths, turns), and a thorough risk assessment. Contingency plans for breakdowns, weather changes, or unexpected obstacles are mandatory.

- Load Securement: Given the often unique shapes and weights of industrial modules, highly specialized lashing and securing plans are developed. Numerous heavy-duty chain binders, slings, and custom-fabricated fixtures are used to ensure the load is absolutely immovable during transit, preventing any shift that could compromise stability.

- Stability Management: The hydraulic suspension system plays a crucial role in maintaining stability, but operators must be trained to manage load height and ground conditions. For extremely high or top-heavy loads, additional bracing or even temporary outriggers might be required during turns or uneven terrain.

- Communication Protocols: A complex convoy, including the modular trailer operator, prime mover drivers (for HMTs), multiple escort vehicles (pilot cars), and often police escorts, relies on constant, clear, and real-time communication (e.g., two-way radios) to coordinate movements, warn other traffic, and manage potential hazards.

- Environmental Awareness: Operating on varied terrain requires vigilance for ground conditions, inclines, and declines. Weather conditions (wind, rain, ice) can significantly impact braking, stability, and visibility, requiring postponements or adjustments.

- Public Safety: Strict measures are implemented to ensure public safety, including temporary road closures, traffic diversions, public notification, and maintaining clear safety perimeters around the moving load.

Crucial Regulatory Requirements:

- Oversize/Overweight Permits: This is the most fundamental requirement. Specialized permits must be obtained from every single state, county, or municipality through which the heavy lift transporter will pass. These permits detail the specific dimensions, weight, approved route, travel times (often restricted to off-peak hours or specific days), and mandated number of escort vehicles.

- Bridge & Infrastructure Clearances/Capacities: Detailed engineering analyses of all bridges, overpasses, culverts, and other infrastructure along the route are required to ensure they can withstand the immense weight and dimensions of the load. Temporary reinforcement or bypasses may be necessary.

- Pilot Car & Escort Regulations: Specific state regulations dictate the number, type, lighting, signage, and training/certification requirements for pilot car operators. Police escorts are often mandatory for the largest moves or in high-traffic areas.

- Driver & Operator Certifications: Drivers of prime movers pulling HMTs, and especially SPMT operators, must possess specialized licenses and certifications for hazardous materials (if applicable) and oversized/overweight transport.

- Vehicle & Equipment Certification: The modular trailer itself, along with its prime mover, must meet rigorous safety and structural integrity standards, undergoing regular inspections and certifications by regulatory bodies.

- Load Securement Regulations: Adherence to Department of Transportation (DOT) or equivalent international standards for load securement is critical, dictating how cargo must be lashed and secured to prevent shifting.

The complexity of these factors means that operating a modular trailer is less about simply “driving” and more about meticulously choreographed, highly engineered logistics that prioritize safety above all else.

Connect with us

Ready to partner? We’re convinced Sunsky Vehicle is your best choice! Reach out through the form or by phone.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact Info

-

+86 13666007515

-

sunskyvehicle@gmail.com

-

No.99 Xiangyu Road, Xiamen Free Trade Zone,HULI DISTRICT, XIAMEN,CHINA Factory address: Liangshan district, Jining city, Shandong, China

Copyright © 2020 Xiamen Sunsky Vehicle Co.,Ltd..All Rights Rese Co.,Ltd..All Rights Reserved.

Get A Quote

The more details you provide, the faster we can quote.

*Our team will answer your inquiries within 12 hours.

*Your information will be kept strictly confidential.