Fuel Tank Truck

Explore our diverse range of fuel tank trucks, including versatile tanker trucks and dedicated fuel delivery trucks, engineered to meet the highest industry standards. We offer robust liquid transport trucks designed with advanced safety features, multi-compartment options, and precise metering systems, ensuring efficient and secure bulk liquid hauling for petroleum, chemicals, and water.

What is a fuel tank truck?

A fuel tank truck, also commonly known as a tanker truck, fuel delivery truck, or liquid transport truck, is a specialized commercial vehicle designed to transport various types of liquids in bulk. Its most distinctive feature is a large, cylindrical tank mounted on its chassis, specifically engineered for the safe containment and delivery of flammable or corrosive materials like gasoline, diesel, aviation fuel, chemicals, or even water. These trucks are built with stringent safety regulations in mind, incorporating features like multiple compartments, advanced pumping systems, and robust safety protocols to prevent spills and ensure precise handling of their sensitive cargo. Fuel tank trucks are vital for maintaining supply chains in industries ranging from energy and construction to agriculture and public services.

Fuel Tank Truck for sale

oil tank truck application scenarios

Fuel tank trucks, including tanker trucks, fuel delivery trucks, and liquid transport trucks, are critical for moving various liquids across diverse industries. Their specialized design ensures safe and efficient bulk liquid logistics.

Petroleum Distribution: The primary use is transporting gasoline, diesel, aviation fuel, and heating oil from refineries or terminals to gas stations, airports, commercial sites, and residential customers.

Chemical Transport: Safely moving industrial chemicals, solvents, and other liquid raw materials between manufacturing plants, storage facilities, and end-users, often requiring specialized lining or construction.

Agricultural Support: Delivering fertilizers, pesticides, or water to farms, or collecting liquid waste. Smaller farm tankers are crucial for on-site fluid management.

Construction Sites: Supplying diesel fuel to heavy machinery and equipment directly on remote construction sites, ensuring continuous operation.

Waste Management: Collecting and transporting liquid waste, such as wastewater, sludge, or hazardous industrial liquids, to treatment or disposal facilities.

Aviation Industry: Specialized aviation fuel trucks deliver jet fuel directly to aircraft at airports.

Standard configuration

-

truck body length

-

12R22.5 Tires

-

LED light system

-

Q345 steel

-

surface paint process

-

Leaf spring suspension

-

condition of the chassis cab

Customizable options

-

truck body height

-

truck body design

-

LHD/RHD

-

capacity

-

vehicle brand

-

accessory(fuel tank,water tank)

-

color

Looking for some new designs ?

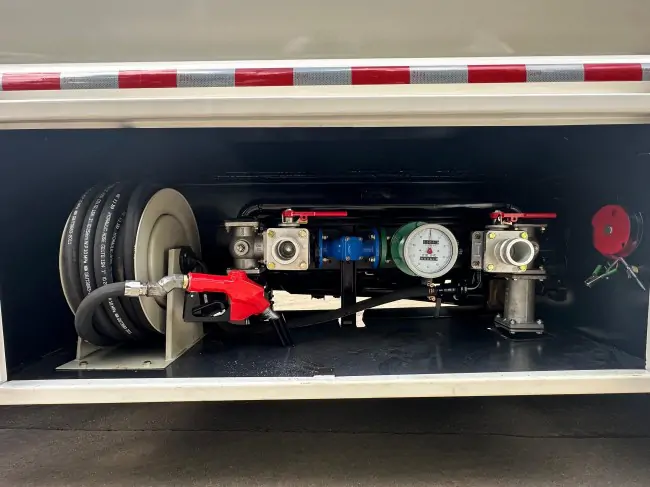

oil tanker truck detail design

The material of the HOWO fuel tank truck body is made of high-quality 4-6 mm thick carbon steel national standard plate and can be made of carbon steel, stainless steel, or, according to the need, aluminum alloy, pure aluminum, rubber-lined, rotomolded, or plastic, or glass steel.

Tanks are available in square, round, oval, and round shapes. Oil pumps are self-priming pumps, gear pumps, and double pumps. It can be designed as a HOWO fuel tank truck, a special vehicle for chemical transportation.

It can be divided into independent bins for different oil products. It can realize pump in and pump out, self-flow, optional flow meter, computerized tax-controlled fuel dispenser, 15-meter fuel reel (with automatic return), and multiple wave-proof partitions in the tank body, which makes the tank body have the characteristics of high strength, stable center of gravity, and safe and smooth vehicle transportation.

All tankers can be designed as chemical trucks and all kinds of HOWO fuel tank truck heating and insulation series tanks; all tankers can be equipped with computerized refueling machines, a wide range of loading tonnage options to meet user requirements, and multiple wave-proof bulkheads inside the tank. High-pressure gas test leak detection is used to make the tank body with high strength, stable centre of gravity, safe and smooth vehicle transportation, etc.

Video of oil truck tanker

HOWO 116HP 4X2 fuel truck

HOWO fuel tank truck

The truck type you are looking for is not found

FAQ

What are the main safety features of a fuel tank truck?

Safety is paramount for any fuel tank truck, also known as a tanker truck or fuel delivery truck, given the flammable or hazardous nature of the liquids they transport. Several key design and operational features are integrated to mitigate risks. Firstly, the tanks themselves are constructed from high-strength materials like aluminum or steel, designed to withstand significant impact and pressure. They are often divided into multiple internal compartments to minimize liquid surging during braking or turning, improving vehicle stability.

Secondly, robust rollover protection bars are typically installed on top of the tank to prevent rupture in case of an overturn. Each compartment has dedicated pressure relief valves and emergency vents that activate if internal pressure builds up, preventing explosions. Thirdly, bottom-loading and vapor recovery systems are common; bottom loading reduces static electricity buildup and vapor emissions, enhancing safety and environmental compliance. Fourthly, advanced braking systems (like ABS and traction control) are standard, along with clear placarding and hazardous materials signage to identify the cargo. Regular inspections, strict adherence to DOT regulations, and highly trained drivers further ensure the safe operation of these vital liquid transport trucks.

How are different types of liquids kept separate in a tanker truck?

Different types of liquids are kept strictly separate in a tanker truck, or fuel tank truck, through the use of multiple internal compartments within the tank. Instead of being one large single chamber, the tank is divided by robust internal walls, known as baffles or bulkheads, into several independent sections. Each compartment has its own fill port, discharge valve, and venting system, ensuring complete isolation of its contents.

This multi-compartment design is crucial for several reasons. Firstly, it allows a single fuel delivery truck to transport different grades of fuel (e.g., regular gasoline, premium gasoline, and diesel) or different chemicals in one trip, maximizing efficiency and reducing the number of trips required. Secondly, it prevents cross-contamination between different products, maintaining their purity and quality. Thirdly, and critically for safety, these compartments, particularly the baffles, also help to control liquid surge (or slosh) during acceleration, braking, or turns. This significantly improves the liquid transport truck’s stability and handling, reducing the risk of rollovers or accidents, which is vital when carrying volatile or heavy liquids.

What are the regulations for operating a fuel delivery truck?

Operating a fuel delivery truck, or tanker truck, is subject to stringent regulations to ensure public safety and environmental protection, given the hazardous nature of their cargo. In the United States, these regulations are primarily governed by the Department of Transportation (DOT) and enforced by agencies like the Federal Motor Carrier Safety Administration (FMCSA). Key requirements include:

Commercial Driver’s License (CDL) with specific endorsements: Drivers must hold a CDL with a tanker endorsement (N) and typically a hazardous materials endorsement (H), requiring specialized knowledge and testing.

Hazardous Materials (HazMat) Regulations: Strict rules apply to placarding, labeling, shipping papers, and emergency response information for the specific liquids being transported.

Vehicle Inspections and Maintenance: Regular, thorough inspections (pre-trip, post-trip, and annual) and preventative maintenance are mandated to ensure all safety systems (brakes, lights, tank integrity, and valves) are in perfect working order.

Tank Specifications: Tanks must meet specific design, construction, and testing standards (e.g., DOT 406 for flammable liquids) to ensure their integrity.

Route Restrictions: Certain routes, tunnels, or bridges may be restricted for liquid transport trucks carrying hazardous materials.

Hours of Service: Strict limitations on driving hours to prevent driver fatigue.

Compliance with these regulations is non-negotiable for anyone operating a fuel tank truck.

What factors affect the capacity and configuration of a fuel tank truck?

The capacity and configuration of a fuel tank truck, or tanker truck, are influenced by several critical factors, ensuring they meet both operational needs and strict regulatory compliance. Firstly, liquid density and type are paramount. Tanks designed for lighter liquids like gasoline will have different volumetric capacities than those for denser products like asphalt or certain chemicals, due to axle weight limitations. The flammability, corrosiveness, or toxicity of the liquid also dictates the tank material (e.g., aluminum for fuel, stainless steel for corrosives) and its internal lining.

Secondly, gross vehicle weight rating (GVWR) and axle configuration are key. Local and federal weight limits (bridge laws, single/tandem axle limits) directly impact the maximum legal payload. A truck might be configured with more axles (e.g., tri-axle or quad-axle) to distribute weight and increase capacity. Thirdly, maneuverability requirements dictate the overall length and wheelbase. Shorter fuel delivery trucks are preferred for urban deliveries, while longer liquid transport trucks are common for highway hauling where capacity is prioritized. Finally, customer delivery methods influence the pumping system, hose reels, and metering equipment—for example, high-volume industrial deliveries vs. precise small-volume commercial fueling. All these factors are carefully balanced to create an optimized and compliant fuel tank truck solution.

Connect with us

Ready to partner? We’re convinced Sunsky Vehicle is your best choice! Reach out through the form or by phone.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact Info

-

+86 13666007515

-

sunskyvehicle@gmail.com

-

No.99 Xiangyu Road, Xiamen Free Trade Zone,HULI DISTRICT, XIAMEN,CHINA Factory address: Liangshan district, Jining city, Shandong, China

Copyright © 2020 Xiamen Sunsky Vehicle Co.,Ltd..All Rights Rese Co.,Ltd..All Rights Reserved.

Get A Quote

The more details you provide, the faster we can quote.

*Our team will answer your inquiries within 12 hours.

*Your information will be kept strictly confidential.