Acid Tank Trailer

Explore our diverse acid tank trailers, engineered for various corrosives and capacities. Featuring specialized materials and advanced safety systems, our chemical tankers ensure secure, compliant, and efficient bulk liquid hauling.

What is an acid tank trailer?

An acid tank trailer, also commonly known as a chemical tank trailer, corrosive liquid tanker, or acid tanker, is a highly specialized semi-trailer specifically designed for the safe and compliant bulk transportation of hazardous, corrosive liquid chemicals. Unlike standard liquid fuel tankers, these trailers are constructed from specific corrosion-resistant materials such as stainless steel alloys, fiberglass-reinforced plastic (FRP), or carbon steel with specialized internal linings (e.g., rubber, phenolic resins). Every aspect of their design, from the tank shell to the valves and fittings, is engineered to prevent leaks, resist chemical attack, and adhere to strict regulatory standards (like DOT hazardous materials regulations) for transporting substances like sulfuric acid, hydrochloric acid, and nitric acid.

Acid Tank Trailer for sale

No products were found matching your selection.

Acid Tanker Trailer application scenarios

Acid tank trailers are critical components in the supply chains of industries that rely on large volumes of corrosive chemicals, ensuring safe and contained transport for various industrial processes.

Chemical Manufacturing & Distribution: Transporting concentrated acids (e.g., sulfuric acid, hydrochloric acid, nitric acid, phosphoric acid) between manufacturing plants, storage facilities, and end-users.

Mining & Metallurgy: Delivering chemicals essential for mineral processing, ore extraction (e.g., leaching agents), and metal finishing operations.

Water Treatment: Supplying various acids and bases (e.g., sodium hypochlorite, sulfuric acid for pH adjustment) to municipal water treatment plants and industrial wastewater facilities.

Agriculture: Hauling liquid fertilizers (e.g., phosphoric acid solutions) or other chemical inputs for large-scale agricultural operations.

Pulp & Paper Industry: Transporting chemicals used in the paper bleaching process or other manufacturing stages.

Petroleum Refining: Moving acids used in various refining processes to and from refineries.

Standard configuration

-

SUNSKY axle

-

12R22.5 Tires

-

LED light system

-

stainless steel material

-

surface paint process

-

Leaf spring suspension

-

toolbox

Customizable options

-

Volume

-

payload

-

shape

-

Tire style and size

-

Discharge valve

-

landing gear

-

BPW/Triangle/FUWA axles as needed

Looking for some new designs ?

Acid Tanker Trailer detail design

Specialized Tank Materials & Linings: The tank body is constructed from specific corrosion-resistant materials such as high-grade stainless steel (e.g., 316L, 304L), fiberglass-reinforced plastic (FRP), or carbon steel with internal linings (e.g., rubber, polyethylene, phenolic) precisely chosen based on the specific acid or chemical to be transported, ensuring maximum chemical compatibility and preventing tank degradation.

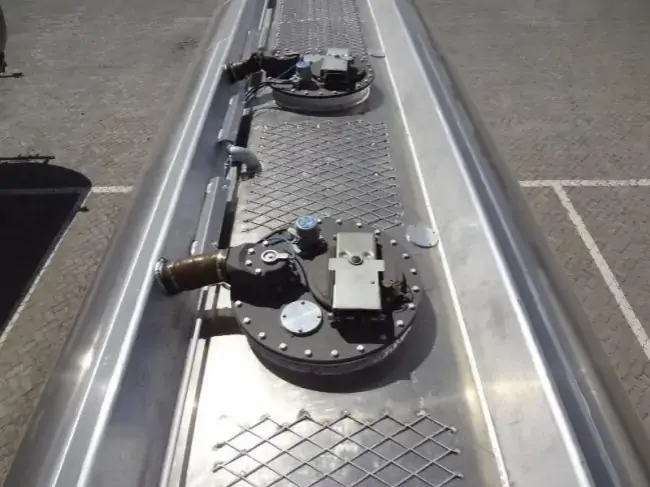

Advanced Safety & Containment Systems: Equipped with multiple layers of safety, including pressure/vacuum relief valves to regulate internal tank pressure, robust emergency shut-off valves for rapid containment in case of a breach, spill containment rails (sumps) around manholes, and dedicated grounding systems to dissipate static electricity, crucial for hazardous chemical transport.

Corrosion-Resistant Loading/Unloading Systems: All valves, pipes, fittings, and pumps (if applicable) are made from materials highly resistant to the specific corrosives being transported. Connections are designed to be leak-proof, often with dry-disconnect couplings, ensuring safe and clean loading and unloading operations without spills or exposure.

Reinforced Chassis & Structural Integrity: Built on a heavy-duty, reinforced steel chassis designed to withstand the dynamic stresses of transporting dense, hazardous liquids. The frame provides exceptional stability, preventing excessive tank movement and ensuring structural integrity, vital for the safe handling of volatile or corrosive payloads.

Secure Manholes & Vents: Top-mounted manholes feature specialized gaskets and robust locking mechanisms to ensure an airtight, leak-proof seal. Venting systems are designed to safely release or recover vapors, preventing pressure buildup while adhering to environmental regulations, essential for chemical transport trailers.

Video of Acid Tank Trailer

acid tank trailer

18cbm acid tank trailer

The trailer type you are looking for is not found

FAQ

What types of corrosive liquids can an acid tank trailer safely transport?

An acid tank trailer, also known as a corrosive liquid tanker or chemical transport trailer, is designed to safely carry a wide range of corrosive and hazardous liquids. This includes common industrial acids such as sulfuric acid (H2SO4), hydrochloric acid (HCl), nitric acid (HNO3), and phosphoric acid (H3PO4), as well as other corrosive chemicals like sodium hypochlorite (bleach), caustic soda (sodium hydroxide), and various industrial solvents. The specific type of internal lining or tank material dictates which chemicals can be safely transported.

How is material compatibility ensured for a chemical tank trailer when transporting different acids?

Material compatibility for a chemical tank trailer is ensured through rigorous selection of tank materials and internal linings specific to the chemicals being transported. For example, stainless steel alloys (like 316L) are used for some acids, while others require rubber lining, FRP (fiberglass reinforced plastic), or specialized polymer coatings. Before loading, the trailer’s documentation and markings (e.g., DOT hazardous material placards) must confirm it is approved and compatible with the exact acid or chemical to prevent corrosion, degradation, or dangerous reactions.

What are the key safety regulations and certifications for an acid tanker?

Acid tankers must adhere to extremely strict safety regulations, most notably those set by the Department of Transportation (DOT) in the United States (e.g., HM-183 and HM-200 regulations for hazardous materials). Key requirements include specific tank construction codes (e.g., DOT 407, DOT 412), comprehensive pressure/vacuum relief systems, emergency shut-off devices, proper labeling and placarding, and regular inspections and hydrostatic testing. Driver training for hazardous materials (HazMat endorsement) is also mandatory for anyone operating a hazardous material tanker.

How do corrosive liquid tankers prevent leaks and spills during transit and unloading?

Corrosive liquid tankers employ multiple layers of defense to prevent leaks and spills. This includes: robust, welded tank construction from chemical-resistant materials; specialized gaskets and seals on all manholes and connections; remote-controlled emergency shut-off valves at both top and bottom outlets; spill containment rails around loading points; and dry-disconnect couplings for hoses that minimize spillage during hook-up and disconnect. Regular pressure testing and stringent maintenance protocols further ensure the integrity of the acid transport trailer.

What kind of maintenance is essential for an acid tank trailer due to corrosive environments?

Essential maintenance for an acid tank trailer in corrosive environments includes frequent internal and external inspections for any signs of corrosion, pitting, or damage to the tank shell and lining. Valves, pipes, and fittings must be regularly checked for leaks and proper operation, and replaced if any degradation is observed. Gaskets and seals require periodic replacement to maintain airtight integrity. Chassis components should also be inspected for corrosive damage, and the braking/suspension systems maintained meticulously to ensure the safe operation of the sulfuric acid trailer.

Are there specific loading and unloading procedures for chemical transport trailers?

Yes, chemical transport trailers follow highly specific and regulated loading and unloading procedures to ensure safety. This includes: proper grounding of the trailer to dissipate static electricity; strict adherence to pressure ratings during pneumatic loading/unloading (if applicable); use of personal protective equipment (PPE) by operators; maintaining a safe distance from other personnel; and having emergency spill kits readily available. Both top-loading and bottom-loading systems require trained personnel to operate specialized valves and pumps, ensuring a controlled transfer of the hazardous material.

Can acid tankers be customized for specific chemical properties or climate conditions?

Yes, acid tankers can be extensively customized for specific chemical properties and climate conditions. Customization options include selecting tank materials or linings precisely matched to the chemical’s corrosivity, concentration, and temperature requirements. Insulation and heating/cooling systems can be added for chemicals that need to be maintained at specific temperatures (hot or cold). Furthermore, specialized pumps, agitation systems, or discharge configurations can be incorporated to optimize for unique chemical handling needs, ensuring the corrosive liquid transport solution is perfectly adapted.

Connect with us

Ready to partner? We’re convinced Sunsky Vehicle is your best choice! Reach out through the form or by phone.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact Info

-

+86 13666007515

-

sunskyvehicle@gmail.com

-

No.99 Xiangyu Road, Xiamen Free Trade Zone,HULI DISTRICT, XIAMEN,CHINA Factory address: Liangshan district, Jining city, Shandong, China

Copyright © 2020 Xiamen Sunsky Vehicle Co.,Ltd..All Rights Rese Co.,Ltd..All Rights Reserved.

Get A Quote

The more details you provide, the faster we can quote.

*Our team will answer your inquiries within 12 hours.

*Your information will be kept strictly confidential.