Garbage Compactor

Our garbage compactors range from residential side-loaders to commercial rear-loaders. Engineered for powerful compression and reliable operation, our waste compactors optimize routes and reduce disposal costs.

What is a garbage compactor?

A garbage compactor, often referred to as a refuse compactor, garbage truck, or waste compactor, is a specialized commercial vehicle designed for the efficient collection, compaction, and transport of solid waste. Its defining feature is a hydraulic compaction mechanism, typically a large ram or packer plate, located within an enclosed body. This mechanism compresses collected refuse, significantly reducing its volume and allowing the truck to carry more waste per trip. This efficiency reduces operational costs, minimizes trips to landfills, and makes waste collection more environmentally friendly. Garbage compactors are indispensable for municipal waste management, commercial waste haulers, and various industrial applications.

Garbage Compactor for sale

No products were found matching your selection.

garbage compactor truck

application scenarios

Garbage compactors, including refuse compactors, garbage trucks, and waste compactors, are essential across a wide range of scenarios for efficient waste collection and management.

Residential Waste Collection: The most common application, where rear-loader garbage trucks or side-loader garbage trucks collect household waste from curbside bins on scheduled routes.

Commercial & Industrial Waste Management: Businesses, retail centers, restaurants, and factories use front-loader garbage trucks to empty large commercial dumpsters, streamlining waste removal from high-volume generators.

Recycling Collection: Specialized recycling compactors are used to collect sorted recyclables (paper, plastic, glass, and metal), often with multiple compartments to keep materials separate while compacting.

Municipal Public Works: Local governments utilize various types of waste collection vehicles for maintaining cleanliness in public spaces, parks, and city facilities.

Event Management: Providing efficient waste removal at large public events, festivals, or temporary venues where significant amounts of refuse are generated quickly.

Healthcare Facilities: Handling general non-hazardous waste from hospitals, clinics, and long-term care facilities, ensuring sanitary disposal.

Standard configuration

-

truck body length

-

12R22.5 Tires

-

LED light system

-

Q345 steel

-

surface paint process

-

Leaf spring suspension

-

condition of the chassis cab

Customizable options

-

truck body height

-

truck body design

-

LHD/RHD

-

payload

-

vehicle brand

-

accessory(fuel tank,water tank)

-

color

Looking for some new designs ?

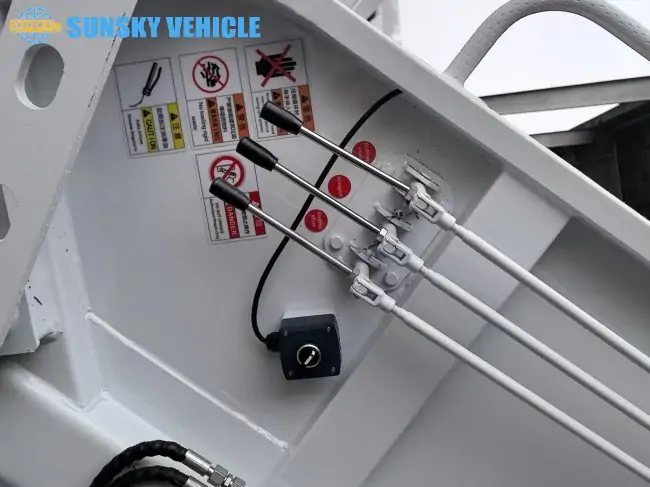

garbage truck compactor detail design

The Sinotruk Howo 4×2 Garbage Compactor Truck is equipped with a powerful and efficient diesel engine that provides exceptional performance and fuel efficiency, thereby reducing operational costs.

The garbage truck’s small size and maneuverability make it easy to navigate through narrow streets and alleys, enabling garbage collection from areas where larger vehicles cannot reach.

The truck is built with high-strength materials and designed for heavy-duty and rugged applications, ensuring longevity and durability.

Sinotruk’s Howo 4×2 Garbage Compactor Truck features a safety system that ensures that workers are safe during operation, reducing the risk of injury and accidents.

With a large garbage box capacity of up to 10-20 cubic meters, this garbage truck can transport large volumes of waste, reducing the need for frequent trips to landfill sites.

The garbage truck is equipped with a hydraulic system that facilitates easy lifting and dumping of waste into the garbage box.

Video of garbage truck compactor

garbage compactor

Garbage Compactor Operation Video

The trailer type you are looking for is not found

FAQ

What are the main types of garbage compactors, and how do they differ?

There are several main types of garbage compactors, also known as refuse trucks or waste collection vehicles, primarily differentiated by their loading mechanism. The most common is the rear-loader garbage truck, where waste is loaded manually or via a tipper mechanism at the back into a large hopper, then compacted by a hydraulic ram. These are highly versatile for residential and commercial routes. Front-loader garbage trucks are designed to lift and empty large commercial dumpsters over the cab into the compaction body, ideal for high-volume commercial and industrial waste.

Side-loader garbage trucks allow for waste collection from the side of the street, either manually or using an automated robotic arm that grasps and empties bins. These are highly efficient for residential curbside collection. Less common but specialized types include grapple trucks (for bulky waste or debris) and roll-off trucks (which transport detachable containers). Each type of waste compactor is optimized for different scales of operation, types of waste, and collection efficiencies, allowing waste management companies to tailor their fleet to specific needs.

How does a waste compactor reduce the volume of garbage?

A waste compactor, or garbage compactor, significantly reduces the volume of garbage through a powerful hydraulic compaction mechanism. Once waste is loaded into the truck’s rear hopper (for rear-loaders) or front compartment (for front-loaders), a heavy steel plate, known as a packer plate or ram, is activated by hydraulic cylinders. This plate pushes the waste into the main collection body of the refuse truck.

As the packer plate moves, it crushes, compresses, and consolidates the garbage, squeezing out air and forcing the materials into a much denser form. This process dramatically reduces the waste’s original volume, allowing the garbage truck to hold two to three times more material than if it were uncompacted. The increased density means the truck can collect more waste per route, reducing the number of trips to disposal facilities like landfills or transfer stations. This not only saves fuel and operational costs but also contributes to environmental efficiency by optimizing hauling capacity. The robust design of the waste compactor ensures effective compression of various types of solid waste.

What are the key safety features on a garbage truck?

Garbage trucks, or refuse compactors, are equipped with numerous safety features to protect both operators and the public, given their size, weight, and the nature of their work in various environments. Firstly, emergency stop buttons are strategically located around the truck (inside the cab and at the rear/side loading points) to immediately halt all compaction and lifting functions in an emergency. Secondly, backup cameras and audible alarms are standard, providing drivers with crucial visibility and warning pedestrians or other vehicles when the truck is reversing.

Thirdly, flashing lights and reflective markings enhance the truck’s visibility, especially during early morning or late evening collection hours. Fourthly, interlocks and sensors prevent the compaction mechanism from operating if safety guards are open or if someone is detected in a dangerous zone. Fifthly, protective guarding around moving parts (like the packer blade) minimizes entanglement risks. Furthermore, modern waste compactors often include advanced driver-assistance systems (ADAS) such as collision avoidance and blind-spot monitoring. Regular maintenance, comprehensive driver training, and adherence to operational protocols are also vital for ensuring the safe operation of these essential waste collection vehicles.

How does a refuse compactor improve efficiency for waste management companies?

A refuse compactor, or garbage compactor, dramatically improves efficiency for waste management companies primarily by maximizing payload and minimizing trips to disposal sites. By compressing waste to a fraction of its original volume, a single garbage truck can collect significantly more material on a given route. This means fewer trips are needed to transport the waste to landfills or transfer stations, leading directly to substantial savings in fuel costs, driver hours, and vehicle wear and tear.

Beyond direct transport efficiency, the compaction process allows for optimized route planning. Companies can service more customers or cover larger areas with fewer vehicles. The various loading mechanisms (rear, front, and side) also enable customization for different collection needs—side loaders for fast residential pickups and front loaders for large commercial bins. This adaptability further enhances operational efficiency. Ultimately, the ability of a waste compactor to condense waste at the point of collection translates into reduced operational expenses, improved service capacity, and a more sustainable waste management process overall.

What maintenance is required for the hydraulic system of a waste compactor?

The hydraulic system is the heart of a waste compactor, or garbage compactor, responsible for the powerful compaction and lifting mechanisms, so its maintenance is crucial for reliable operation. Firstly, regular inspection of the hydraulic fluid is paramount. This includes checking fluid levels (ensuring they are within the proper range), assessing its condition (looking for cloudiness, discoloration, or contamination), and replacing it according to the manufacturer’s schedule. Dirty or low fluid can lead to pump damage and reduced compaction force.

Secondly, routinely inspect all hydraulic hoses, fittings, and cylinders for any signs of leaks, cracks, bulges, or excessive wear. Leaks not only waste fluid but also indicate potential system pressure loss. All seals on the hydraulic cylinders should be checked for integrity. Thirdly, hydraulic filters must be changed regularly to ensure the fluid remains clean and free of debris, which can clog valves and damage components. Fourthly, ensure the Power Take-Off (PTO) unit, which powers the pump, is engaging smoothly and securely. Lastly, regular greasing of pivot points and moving parts associated with the hydraulic ram is essential to reduce friction and wear. Diligent hydraulic system maintenance ensures the continuous, powerful performance of any refuse truck.

Connect with us

Ready to partner? We’re convinced Sunsky Vehicle is your best choice! Reach out through the form or by phone.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact Info

-

+86 13666007515

-

sunskyvehicle@gmail.com

-

No.99 Xiangyu Road, Xiamen Free Trade Zone,HULI DISTRICT, XIAMEN,CHINA Factory address: Liangshan district, Jining city, Shandong, China

Copyright © 2020 Xiamen Sunsky Vehicle Co.,Ltd..All Rights Rese Co.,Ltd..All Rights Reserved.

Get A Quote

The more details you provide, the faster we can quote.

*Our team will answer your inquiries within 12 hours.

*Your information will be kept strictly confidential.