Refrigerated Truck

Our refrigerated trucks and reefer vans are engineered to maintain precise temperatures for perishable cargo. We offer reliable cold chain transport solutions with superior insulation and powerful refrigeration units, ensuring your goods arrive fresh, safe, and on time. Trust us for dependable temperature-controlled logistics.

What is a refrigerated truck?

A refrigerated truck, commonly known as a reefer truck or refrigerated van, is a specialized commercial vehicle designed to transport perishable goods at controlled temperatures. Unlike standard box trucks, a refrigerated truck features an insulated cargo compartment equipped with a self-contained refrigeration unit. This unit actively cools the interior, maintaining a specific temperature range, from frozen to chilled, regardless of external conditions. Essential for industries dealing with sensitive products, refrigerated trucks ensure the integrity and safety of food, pharmaceuticals, flowers, and other temperature-sensitive items from pickup to delivery.

Refrigerated Truck for sale

refrigerator truck application scenarios

Refrigerated trucks, including reefer trucks and cold chain transport vehicles, are indispensable across numerous industries that rely on temperature-controlled logistics.

Food Distribution: Essential for transporting fresh produce, meats, dairy products, frozen foods, and baked goods from farms or processing plants to grocery stores, restaurants, and catering services.

Pharmaceuticals & Healthcare: Crucial for the safe delivery of vaccines, medications, blood products, and other sensitive medical supplies that require strict temperature control to maintain efficacy.

Floriculture: Used to transport delicate flowers and plants, preserving their freshness and preventing wilting during transit from growers to florists or event venues.

Chemical & Specialty Products: Hauling certain chemicals, adhesives, or industrial materials that require specific temperature conditions to prevent degradation or ensure stability.

Catering Services: Delivering prepared meals and ingredients for events, ensuring food safety and quality by maintaining appropriate hot or cold temperatures.

Seafood & Meat Industry: Transporting fresh and frozen seafood, poultry, and red meats from processing facilities to markets, maintaining strict hygiene and temperature standards.

Standard configuration

-

truck body length

-

12R22.5 Tires

-

LED light system

-

Q345 steel

-

surface paint process

-

Leaf spring suspension

-

condition of the chassis cab

Customizable options

-

truck body height

-

truck body design

-

LHD/RHD

-

payload

-

vehicle brand

-

accessory(fuel tank,water tank)

-

color

Looking for some new designs ?

refrigerated van truck detail design

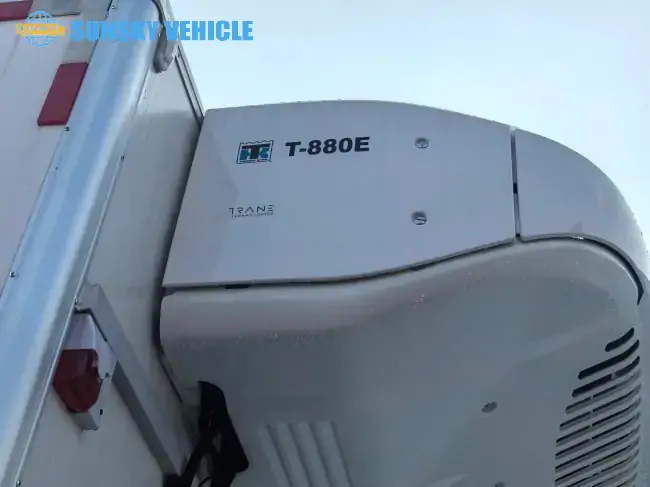

The refrigerated truck refrigeration unit is equipped with high-quality compressors, condensers and evaporators that work together to effectively control and regulate the temperature of the cold storage compartment. In addition, it is equipped with advanced sensors and controllers that monitor the temperature and adjust the refrigeration system accordingly, ensuring maximum efficiency and minimum energy consumption.

The aluminum rails of refrigerated trucks are lightweight and strong in structure, making them easy to handle even the most demanding transportation conditions. They are also corrosion-resistant and rust-proof, and can withstand moisture and other environmental factors. In addition to this, aluminum rails are easy to install and maintain. Its user-friendly design ensures that the rails can be easily adjusted or replaced as needed, ensuring that the refrigerated compartment remains safe and stable during transportation

The rear compartment door of a refrigerated truck is an important component for maintaining the temperature and quality of the product during transportation. If the rear compartment door malfunctions, it may lead to poor temperature control, resulting in product deterioration and financial losses. We provide professional installation and repair services for refrigerated truck rear compartment doors. We use high-quality materials and equipment to ensure that your rear compartment door installation or repair is to the highest standards.

The side sliding door of a refrigerated truck comprises a door frame arranged on the side panel of the refrigerated truck compartment and a door panel matched with the door frame; an upper track is arranged at the upper end of the outer door frame, a lower track is arranged at the lower end of the outer door frame, and a middle track is arranged on the side panel of the compartment, and the middle track is located on one side of the opening direction, which can ensure the synchronous and balanced operation of the door panel in the front and rear directions when opening and closing the door.

Video of refrigerated transport trucks

FAW 5T Refrigerated Truck

FAW 58T Refrigerated Truck

The truck type you are looking for is not found

FAQ

What types of goods require refrigerated truck transport?

Refrigerated truck transport, often carried out by reefer trucks or refrigerated vans, is essential for any goods that are perishable or temperature-sensitive. The most common categories include food products such as fresh produce (fruits and vegetables), dairy (milk, cheese, and yogurt), meats (fresh and frozen), poultry, seafood, baked goods, and prepared meals. Maintaining specific temperatures is crucial for preventing spoilage, inhibiting bacterial growth, and preserving freshness from farm to table.

Beyond food, pharmaceuticals and medical supplies like vaccines, blood plasma, and certain medications strictly require temperature-controlled transport to maintain their efficacy and safety. Even small temperature fluctuations can render some pharmaceutical products unusable. Additionally, floriculture products (flowers, plants) need cooling to prevent wilting and extend shelf life. Certain chemicals or specialty materials also require temperature stability to prevent degradation or ensure safe handling. Ultimately, any product that could be compromised by heat, cold, or temperature swings relies heavily on the precise environmental control offered by a dedicated cold chain transport vehicle.

What are the different types of refrigeration units available for refrigerated vans?

Refrigeration units for refrigerated vans (or reefer trucks) come in several types, each designed for specific needs and power sources. The most common type is a diesel-powered unit, which is self-contained and typically mounted on the front bulkhead of the truck body. These are robust, provide powerful cooling capacity, and are ideal for long hauls and maintaining deep-frozen temperatures, as they operate independently of the truck’s engine.

Another significant type is electric-powered units, which can be standby electric (plugged into shore power when the truck is parked for continuous cooling without running the diesel engine) or all-electric/battery-electric, especially for smaller refrigerated trucks used in urban last-mile delivery, offering quieter, zero-emission operation. Some systems are truck engine-driven (also known as “direct drive”), where the refrigeration compressor is powered directly by the truck’s engine. These are typically found on smaller refrigerated vans and are more cost-effective but only cool when the engine is running. Lastly, specialized units might involve cryogenic systems (using liquid nitrogen or CO2 for ultra-low temperatures) or multi-temp units that can maintain different temperature zones within the same cargo area, providing ultimate flexibility for diverse perishable loads.

How does the insulation affect the efficiency of a cold chain transport vehicle?

The insulation in a cold chain transport vehicle, such as a refrigerated truck or reefer van, is absolutely critical for its overall efficiency and performance. Its primary role is to minimize heat transfer between the external environment and the cargo compartment. Effective insulation creates a strong thermal barrier, significantly reducing the amount of heat that can seep into the conditioned space. This directly translates to several benefits for the efficiency of the refrigerated transport.

Firstly, energy consumption is lowered. When insulation is highly effective, the refrigeration unit doesn’t have to work as hard or as frequently to maintain the desired temperature. This reduces fuel consumption for diesel-powered units or extends battery life for electric ones, leading to significant operational cost savings. Secondly, it ensures temperature stability. Good insulation prevents rapid temperature fluctuations inside the cargo area, providing a more consistent and reliable environment for sensitive products, even when outside temperatures are extreme. Thirdly, it reduces wear and tear on the refrigeration unit, as it operates less frequently, extending its lifespan. In essence, high-quality insulation is the silent hero of temperature-controlled logistics, underpinning the economic and operational viability of any refrigerated truck.

What are the hygiene and cleaning requirements for a refrigerated truck?

Hygiene and cleaning requirements for a refrigerated truck, or reefer truck, are exceptionally strict, especially when transporting food products or pharmaceuticals, to prevent contamination and ensure product safety. The interior of the refrigerated van must be constructed with smooth, non-porous, and washable materials like fiberglass-reinforced plastic (FRP) or aluminum, making it easy to clean. After each load, particularly if it involved fresh produce, meats, or anything that could leave residues, the entire cargo area must be thoroughly swept and washed down with appropriate food-grade detergents and sanitizers.

This cleaning process typically involves removing all debris, scrubbing surfaces (walls, floor, ceiling, and any racks), rinsing thoroughly with potable water, and then allowing the interior to completely dry to prevent mold or mildew growth. Regular disinfection is also crucial. For some sensitive products, specific chemical sanitizers might be required. Drivers and operators must also ensure proper personal hygiene. Failure to adhere to stringent cleaning protocols can lead to cross-contamination, bacterial growth, and product spoilage, resulting in significant financial losses, health risks, and regulatory penalties for the cold chain transport provider.

Connect with us

Ready to partner? We’re convinced Sunsky Vehicle is your best choice! Reach out through the form or by phone.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact Info

-

+86 13666007515

-

sunskyvehicle@gmail.com

-

No.99 Xiangyu Road, Xiamen Free Trade Zone,HULI DISTRICT, XIAMEN,CHINA Factory address: Liangshan district, Jining city, Shandong, China

Copyright © 2020 Xiamen Sunsky Vehicle Co.,Ltd..All Rights Rese Co.,Ltd..All Rights Reserved.

Get A Quote

The more details you provide, the faster we can quote.

*Our team will answer your inquiries within 12 hours.

*Your information will be kept strictly confidential.