Introduction of Cement Tanker Trailer

I. An introduction of bulk cement tanker trailer

The cement tanker trailer is also called powder material transport trailer, which is composed of special vehicle chassis, bulk cement tanker body, trachea system, automatic unloading device and other parts.

It is suitable for bulk transportation of powder dry materials with particle diameter of no more than 0.1mm, such as fly ash, cement, lime powder, ore powder and alkali. Cement tanker trailer mainly used for cement factory, cement warehouse and large construction site,it can save a lot of packaging materials and loading and unloading labor.

The bulk cement tanker SUNSKY produced will help you reduce the loss rate of cement power material and improve the loading and unloading efficiency.Bulk cement tanker trailers have different capacities, ranging from 20m/CBM, 30m/CBM, 40m/CBM, 50m/CBM and 70m/CBM. Each type has a different number of axles, such as 2, 3, and 4 axles.

II. Function of bulk cement tanker trailer

Suitable for transporting fly ash, cement, lime powder, ore powder and other particles diameter is not greater than 0.1mm dry material and air pressure unloading.Unloading vertical height reaches 15m, horizontal conveying distance can reach 5m.

3 axle cement bulk tank trailer

III. Configuration of bulk cement tanker trailer

The basic structure includes frame and traction pins,suspension system, automobile chassis, axle and wheels,support device,brake and its operating device,electrical system,tank, chassis and management system. Here is an introduction to some of the structures:

1. Frame and Traction Pins: Frame is low-alloy steel welded structure of space frame type.The frame is made up of two T-shaped longitudinal beams welded to the beam to support the load.Tow pin and tow pin plate attached to tractor under front frame.The traction pin is assembly type for easy replacement.An air brake joint and a wire connection socket are arranged on the front beam of the frame. The front and rear of the frame and the side are equipped with lighting or signal devices.

2. Suspension system: after the lower part of the longitudinal beam is welded with a suspension device to support, and before the lower part is provided with a supporting device to support.Suspension system is a three-axis plate spring suspension, is used to support the load, and has the function of absorbing driving vibration.The leaf spring suspension system is fastened to the axle body with U-bolts.The parking brake is controlled by the energy storage spring brake system, and the wheel brake serves as the parking brake. This device is used when parking or standing on the slope.

3. Axle and wheels: three axle assemblies of the same structure are installed under the suspension system. The axle is a square tube axle, on which a platform for installing a plate spring suspension and a bracket for installing a brake chamber are arranged. The axle head is used to install wheels, hubs, brakes, etc.

4. Support device: in order to make the semi-trailer out of the tractor head can be reliably parked, the front of the frame is equipped with left and right linkage or left and right single movement of two supporting devices.It is composed of screw transmission mechanism, bevel gear transmission mechanism, double speed reduction box, transmission rod, operation handle, etc.When the handle is pushed in, high speed lifting can be obtained by rotating, and when the handle is pulled out, low speed can be obtained by rotating. When the base is in contact with the ground, only low gear lifting can be used.

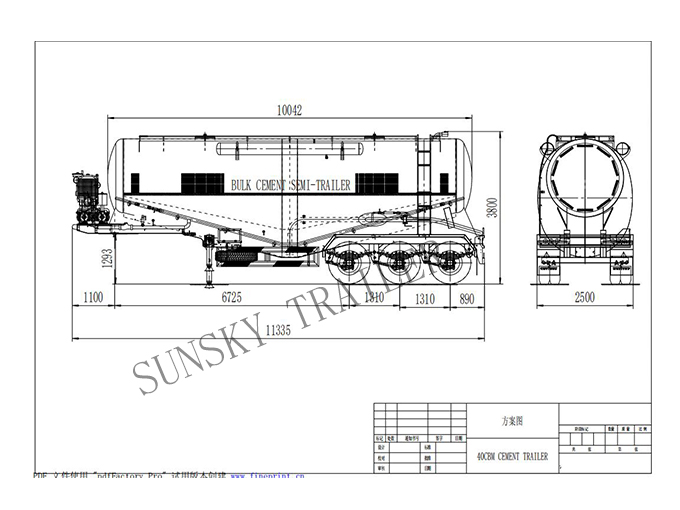

40CBM BULK TRAILER drawing

5. Brake and its operating device: Cement bulk semi-trailer adopts double pipeline pneumatic braking system and equipped with anti-lock braking system (ABS). The braking system mainly consists of gas joints, gas filling pipelines, operating pipelines, emergency relay valves, air storage cylinders, brake chambers and wheel brakes.The air joint of the charging pipeline is connected with the air storage cylinder of the tractor, and the air joint of the operating pipeline is connected with the brake valve of the tractor. When the bulk cement semi-trailer brakes, each brake chamber acts simultaneously. When the driver's foot steps on the brake pedal, each brake chamber of the cement semi-trailer acts to realize normal foot braking.When the inflatable pipe leaks or bursts, or the tractor suddenly disengages from the semi-trailer when driving, resulting in the pipeline detachment, the semi-trailer can brake automatically. When the interlink semi trailer stops and the tractor is separated from the semi-trailer, the semi-trailer can brake by itself. If the parking time is short, there is no need to use the parking brake.

6. Electrical system: the bulk cement semi-trailer is equipped with the international general electrical system to adapt the tractor. There are electrical connector sockets in the front crossbeam of the frame.The rear part of the frame is provided with a brake light, a turn signal, a parking light, a reverse light, a license plate light, a fog light and a triangular reflector. The front and both sides are provided with a front light and a width indicator light, a side sign light, and the right front part is equipped with an ABS indicator light.

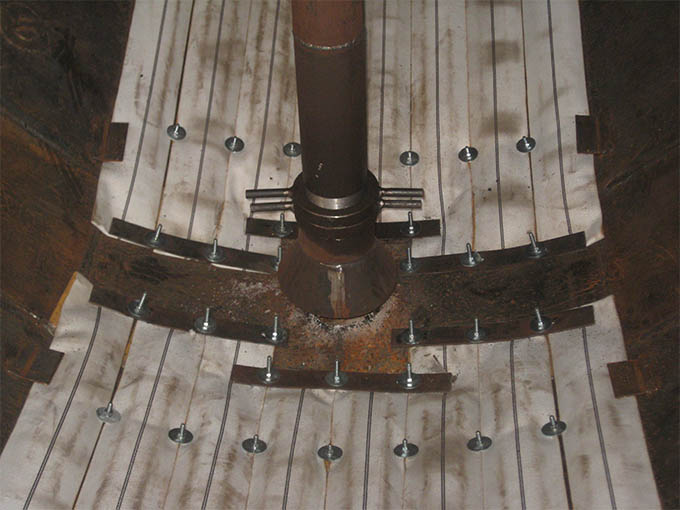

7. Tank: The cement tanker of the powder material mainly consists of the tank body, the upper feeding port of the tank body, the fluidized bed, the discharge pipe assembly, the intake pipe and other accessories. Two or three feeding ports are provided at the top of the tank.The tank is all metal welding parts, the tank is made of ordinary carbon structure steel plate flow round butt, stamping head welded sealed container loaded with materials, volume can range from 20 to 70m³. There are manholes and walkways above for loading and unloading and maintenance personnel to enter the tank. The tank inside has a fluidized bed air chamber.The air chamber is composed of a slide plate and an air bag, so that the compressed air can be discharged from the discharge pipe after being fluidized through the powder material packed in the air bag. The head is blanked by the plasma CNC cutting machine, and then spun by the imitation edge spinning machine once to increase the strength. It is not allowed to use manual knocking to turn the edge to avoid material damage.

8. Chassis:You can choose many China brands of chassis, such as JIEFANGchassis, SINOTRUCK chassis, JAC chassis, you can choose any one according to the actual demand.

9. Management system:There is an air inlet pipe for the front and rear air chambers of bulk cement trailer, which can be opened and controlled separately through the ball valve.

IV. SUNSKY bulk cement tanker trailer production process

1.The exterior design of the cement tanker should not only be beautiful, but also practical:

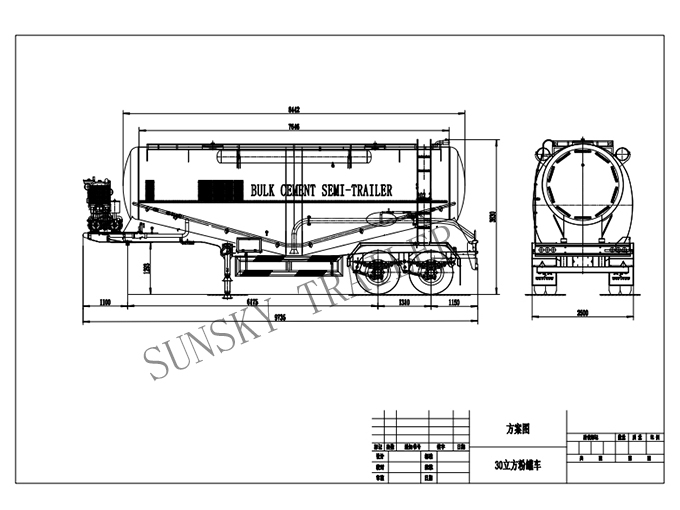

30CBM BULK TRAILER drawing

After the design and drawing of the cement tank trailer is completed, the actual manufacturing work is carried out.

SUNSKY adopts laser cutting, which can improve the accuracy to 0.01mm. The mirror incision molding, can be cut as much as possible,can reduce the cutting hot melt area as much as possible, so that the steel plate elements do not change, no loss of rigidity and no stress concentration phenomenon.

Then, automated NC rolling machine is used for control, the cylinder is formed once, the inside of the plate will not be damaged, and the forming quality is stable and reliable.

Next, the roller needs to be assembled. SUNSKY cement tanker adopts a frame assembly process, which makes the left and right rollers butt together. Such process equipment can ensure that the cement tanker will not be deformed when assembly and the appearance is beautiful.

And the size of the cylinder and the design size are exactly the same, which can make the cylinder has an ideal force layout, so that the cement tank will not crack easily.

After the tank has been assembled, it needs to be welded. Good welding process not only can keep the welding seam of the cement tanker beautiful, but also can ensure that the steel plate welding place will not concentrated stress, keep the tank steel plate has a good strength.

SUNSKY powder cement tanker body adopts automatic welding process, single-sided welding and double-sided forming, so that the tank has better strength.

After the shape of the cement tanker is determined, it is also necessary to accurately locate the tank.Only accurate positioning, can as far as possible to avoid traction pin wear, suspension tire wear, trailer tail slaying and center of gravity deviation and other problems.

Tank body adopts the chassis horizontal positioning platform, With automatic height adjustment function.According to the height difference of different brands of tractor saddle, to ensure that the trailer chassis and tractor saddle can be completely consistent.

2.Tank unloading fast and less residual materials, internal design needs to be professional:

Next, let's look at the fluidized bed design structure inside the cement tanker.

The Angle of the cylinder and side slide of the powder tank trailer is 2-3 degrees greater than other tanks in the industry, which can improve the fluidity of materials, reduce the residual amount of materials inside the tank, and unload materials as soon as possible,which the fastest unloading speed can reach 1.5 tons/min.

Powder cement tanker discharge port also adopts the increased design, which can ensure that the material can be fully supplied when unloading, and can achieve the fastest speed of unloading material, and The triangular stability principle is used in the reinforcement support of the discharge pipe can ensure that in the process of unloading, pipeline no displacement, stability is the best.

3.Spray painting process is very important, not only to ensure the quality of trailer paint but also pay attention to environmental protection:

After the design of external shape and internal structure is completed, it is necessary to spray paint the tank body. SUNSKY cement tankers are designed with a spray + powder process that allows the coating to last 5-8 years without fading.

Finally, the preliminary treatment does not contain phosphorus and heavy metal materials,more environmentally friendly.

Finally, layout and assemble the outer piping of the tank. In the pipeline, we should pay special attention to the details, the ball head adopts stainless steel design, it is beautiful and useful, enhanced external support, can make the tank bear better force. Laser weld and no stress concentration make the life of the cement tanker longer.

4.Inspection work is necessary. New vehicle can only be driven into the market if they meet the inspection standards:

When a new trailer model is completed, it can only be considered a qualified product after passing all strict standards.

SUNSKY has testing tower, complex road conditions, and vehicle inspection center test site.They can accurately test the residue discharging speed and the best location of tank size, the stability of trailer and the trailer's brake and safety performance,it can be use only the performance of the trailer has reached the national standard.

5.Finally, service is the beginning of sales, no matter how high quality products also need satisfactory service:

An excellent product not only needs professional design method and good manufacturing process, but also needs satisfactory service, which can be regarded as a complete ecosystem.

2 axle cement bulk tank trailer

V.The advantages of SUNSKY cement tanker trailer

1.Bulk cement tanker trailer’s tank is made of high strength wear-resistant steel, which has the advantages of light weight and more durability to ensure a longer life span.

2.The main frames using high-strength steel materials, have a light dead-weight, ensure its resistance to twisting forces, shock and bump, meet load requirements on different kinds of road.

3.The cement tanker trailer use the latest flow structure design,no guide plate structure.The load capacity is bigger and have a lower center of gravity.

4.The bulk cement trailer use no guide plate structure design,has the advantages of light weight, low residue and double alloy to reduce tare weight

5.The new unique no gas chamber structure design and original closed chamber structure design, make full use of fluidization principle, optimization of the traditional gas chamber energy principle. To ensure the normal use of customers while reducing operating costs

6.The design and reasonable parameter matching of the canvas belt type fluidized bed makes the residual rate lower, the unloading rate is quicker, saves the cost and improves the efficiency.

4 axle cement bulk tank trailer

7.Adopt the domestic and foreign famous brand accessories and parts,such as Weichai engine, Suk air compressor,BPW Axles,Jost Landing Gear, ensure the durability of bulk cement trailer.Help you save costs on operation and maintain.

8.Special welding machine to weld the tank body from one side but form smooth, sturdy and uniform welds on both sides.Use advanced welding technology and experienced welder to make sure the high safety and no air leak.

9. The integrated tank has the characteristics of high overall strength, good rigidity, good pressure bearing and good service performance.

The design of the fluidized bed in the tank is scientific, and the layout is reasonable, which can effectively shorten the discharging time, reaching 1.4t /min, improve the volume utilization ratio of the tank, and reduce the residual ash rate, which is 0.2%. Bulk cement trailer tank adopts double cone inward inclined horizontal structure, double tube air intake, double cylinder feeding, the discharge speed and residual rate are in line with the industry standard requirements.

VI. How does a bulk cement tank trailer works?

Powder material transport semi trailer has its own engine power and drives the on-board air compressor through the force taker.Compressed air is piped into an air chamber at the lower part of the sealed tank, the cement on a fluidized bed is suspended into a fluid state.When the pressure in the tank reaches the rated value, the discharge butterfly valve is opened, and the fluidized cement is transported through the pipeline.

VII. Discharge conditions of SUNSKY cement tanker trailer

1. The pipeline system is fitted with reasonable auxiliary blower and anti-wear device to realize smoother unloading process and faster unloading speed.

2. Wide area fluidized bed with a large angle tanker,so unloading faster and less residue.

3. Linear arrangement of the intake inlet line is smoother,make the unloading faster.

4. Fast discharging and a small amountof residual materials. residual volume less than 50kg, the discharge speed up to 1.53cbm/min.

5. The body of the shell has been applied for the national patent, and the new type of tank body has guaranteed the effective volume to reach 97%--98%, and it can create more value than the same kind of product.

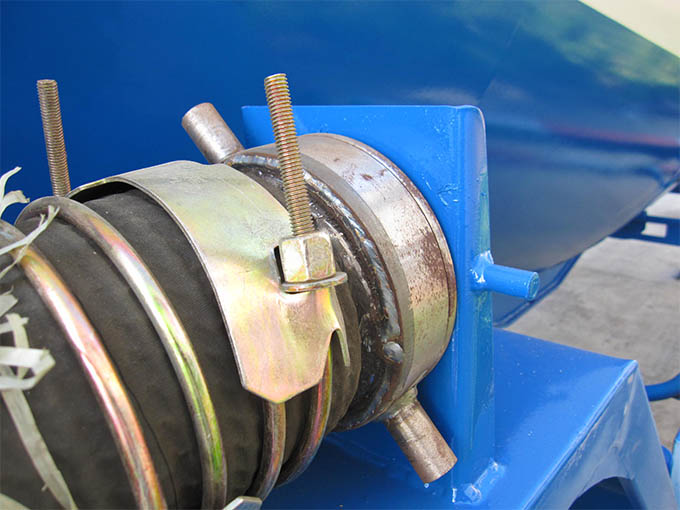

discharge hose

VIII. Safety Operation Rules for Bulk cement Tank Trailer Unloading

1. Before opening the feed port, the pressure relief valve and the ball valve of the intake pipe must be opened first, and the material cover must be opened after the residual gas in the cement tanker is eliminated to avoid injury accidents.

2. Often pay attention to whether the pressure gauge is working normally, to prevent the pressure gauge failure, overpressure, and the occurrence of tank burst leak.

3. Often check the safety valve to ensure that the pressure relief begins at 0.2Mpa, and the pressure in the tank shall not exceed 0.2Mpa.

4. Often check whether the running table is working normally, so as not to overturn and damage the air compressor and force extractor.

5. Often listen to the force and air compressor rotation sound, if there is abnormal sound, should immediately stop troubleshooting.

IX.Powder tank truck unloading steps

1. Before unloading, check whether the discharge disc valve, external air source interface, exhaust valve and two feed ports are closed and tightened. If not, tighten them first to prevent air leakage.

2. Start the engine and shift the transmission to neutral, and step on the clutch pedal to completely separate the gearbox from the engine.

3. Open the solenoid valve switch of the force collector, and slowly release the clutch pedal to make the air compressor rotate.

4. Adjust the control handle of the control mechanism, adjust the speed of the air compressor to about 900r/min, and stabilize it.

5. When the pressure reaches 0.18Mpa, open the blowing pipe first, and then open the discharge disc valve of the front and rear storehouses to begin unloading. After that, the air compressor pointer will stabilize a certain value.

6. When the pressure drops to 0.04Mpa, the back bin has been unloaded, close the blowing pipe, open and close the back bin valve several times, and then close the back bin valve and the back bin inlet valve, that is, only let the front bin discharge, and then the pressure will rise and stabilize to a certain value.

7. When the pressure of the barometer reaches 0MPa, close the air compressor (close the force switch) and the discharge disc valve after unloading.

discharge valve

X. Guide for the use of cement tanker trailer

1. Do not overspeed or overpressure when driving the bulk cement trailer truck. Overspeed or overpressure will seriously damage the air compressor. The highest speed of the machine is shown in the table of main technical parameters, and the working pressure is 0.2mpa.

2. Do not start or stop the air compressor quickly, but increase or slow down slowly, otherwise, the pressure will damage the air compressor.

3. Do not change the rotation direction of the air compressor, otherwise, the oil pump will seriously damage the machine.

4. Do not stop the air compressor before decompression, otherwise, powder material may flow back into the cylinder, causing serious damage to the air compressor.

5. Oil standard shall be checked before starting up. The oil level shall not be lower than the lower limit of the oil standard; It is necessary to check frequently whether the oil pump is supplied or not. If not, stop the pump immediately for inspection. Otherwise, the lack of oil will seriously damage the air compressor.

6. Change the lubricating oil on schedule. After using the new trailer for 30 hours, drain the oil from the crankcase, clean the inside of the crankcase and the oil filter net, and then change the oil. Change the oil as mentioned above once a year thereafter.

7. Check and clean the oil filter. Under normal conditions, check and clean once a quarter, if the machine utilization rate is high, check and clean once a month.

8. The lubricating oil used in this trailer is diesel oil. Mixed use of lubricating oil of different grades is prohibited, otherwise deterioration of lubricating oil will affect the lubrication effect.

9. Maintain and clean the air filter every 30 hours. While rotating the filter element, it is blown inward and outward with compressed air pressure less than 0.6mpa. After five times of maintenance, please replace the new filter element. Do not clean the filter element with oil or water.

XI.Powder cement tanker trailer maintenance

1. The trailer chassis: according to the selection of the trailer chassis manual provisions.

2. Air compressor: according to the provisions of the air compressor manual.

3. The force taking device: often pay attention to check the lubrication situation and operation condition regularly, if there is abnormal sound, the reason should be found out and eliminated in time, the gear bite and wear should be checked once a year, and can not overspeed operation.

4. Gas path: check the sealing situation frequently, If there is air leakage, remove it in time. Check the working condition of each valve frequently, if it fails, it should be repaired or replaced. The safety valve is guaranteed to open when the pressure is 0.2Mpa, and the pressure in the cement tanker shall not exceed 0.2Mpa.

5. Tank: regularly check whether there is air leakage in the tank weld. If this phenomenon is found, repair welding should be carried out in time.

6. Tank chamber: often check the gas chamber canvas, if the damp airtight or damaged, should be replaced in time. Check whether the gas chamber is compacted or not. If there is air leakage, it will affect the discharge effect and should be eliminated in time.

XII. Why is aluminum alloy bulk cement tank trailer the mainstream product in the future?

Lightweight technology is the theme of the development of bulk cement tank trailer technology, with the increase of domestic control over, control limits, aluminum alloy bulk cement tank trailer in the domestic market on the rise.

1.Aluminum alloy powder tank truck has a broad development prospect

With the increasingly strict regulations on overloading, limiting, safety and environmental protection of modern logistics vehicles, "lightweight" technology has become a hot issue in the special purpose vehicle industry at the present stage.

Domestic markets have set off a climax of demand for small cubic lightweight powder cement tank semi-trailer, but the high-strength steel powder cement tank semi-trailer has become the bottleneck of the current lightweight technology.

Aluminum alloy material has the characteristics of low density, high strength and corrosion resistance, etc. Aluminum alloy has become the preferred material for the application of lightweight technology of powder cement tank semi-trailer. Bulk cement transport semi-trailer whose main structure (tank body, frame) is made of aluminum alloy has emerged in the domestic market and is on the rise.

2.Advantages of aluminum alloy materials used in powder cement tank semi-trailer

1. The quality of the reconditioning is reduced

The density of aluminum alloy is only about 1/3 of the steel. The application of aluminum alloy material on the powder cement tank semi-trailer can greatly reduce the quality of the preparation of the powder cement tank semi-trailer.

Taking 38m³ horizontal powder cement tank semitrailer as an example, the main structure (tank, frame) and its accessories are high-strength steel structure of powder cement tank semitrailer with a ready mass of 6.15~6.5t, while the main structure (tank, frame) and its accessories are aluminum alloy structure of powder cement tank semitrailer with a ready mass of 5.0t. 38m³ aluminum alloy structure can be high strength steel structure horizontal powder tank semi-trailer with light weight of 1.2~1.5t.

2. High economic efficiency

The maximum gross weight of a six-axle semi-trailer shall not exceed 49t.

In order to obtain better economic benefits, it is particularly important to lighten the vehicle to increase the effective loading capacity.

According to the feedback of Chinese research users, the transportation cost of each ton of cement is about 50 yuan per 100 kilometers, and each ton of cement can earn about 100 yuan more per day. The transportation cost of each ton of cement for 100 kilometers is about 40 yuan, and every extra 1t of cement transported can earn about 140 yuan more per day.

According to the calculation of 300 days of operation per year (busier year), in the case that the weight of aluminum alloy powder cement tank semi-trailer is reduced by 1.5t, it can earn 45,000-63,000 yuan more per year.

3. Energy conservation and emission reduction

According to the research report of the European Aluminum Association, every 100kg vehicle weight reduced, 100km fuel consumption can be reduced by 0.6L, and every 1L fuel saved can reduce CO2 emissions by 2.3kg.

If an aluminum alloy horizontal powder cement tank semi-trailer loses 1.5t weight and travels 120,000 km annually, it can save 5400L fuel and reduce CO2 emission by 14.42t according to half of the no-load mileage calculation.

4. Corrosion resistance

Aluminum alloy contact with air, the surface will naturally form oxide film, has good corrosion resistance, so the aluminum alloy structure of powder cement tank semi-trailer can not be used as antirust paint coating on the surface.

Aluminum alloy powder cement tank semi-trailer can not only reduce the cost of paint coating, but also reduce the damage to the operator's body and the pollution to the environment.

5. High recovery value

Because of the high corrosion resistance of aluminum alloy, when the vehicle reaches the mandatory scrap life, there is no significant damage to the trailer body, and the recovery value of aluminum alloy high strength steel is high.

According to relevant data, the current price of scrap aluminum is about 11,000 /t, and the price of scrap iron is about 0.19 million /t. If a semi-trailer of aluminum alloy powder tank uses 2T aluminum alloy material, the recycling price of aluminum alloy material is 22,000 yuan.

At the same time, the semi-trailer of the same volume of high-strength steel powder tank uses 3.5T high-strength steel, and the recycling price of the steel is 66,500 yuan (at the same time, the corrosion resistance of the steel is poor, and the recycling price of the high-strength steel is lower than this value).

Leave a Comment